LEADING EXPERTISE IN

SURFACE COATINGS

Request a quote

KNOWLEDGE. QUALITY. COMMITMENT.

Founded as CR3X in 1994, Tekad Industries specializes in the repair and refurbishment of steel surfaces. Our team is made up of veteran engineers, metallurgists, machinists, and chrome technicians.

OUR SERVICES

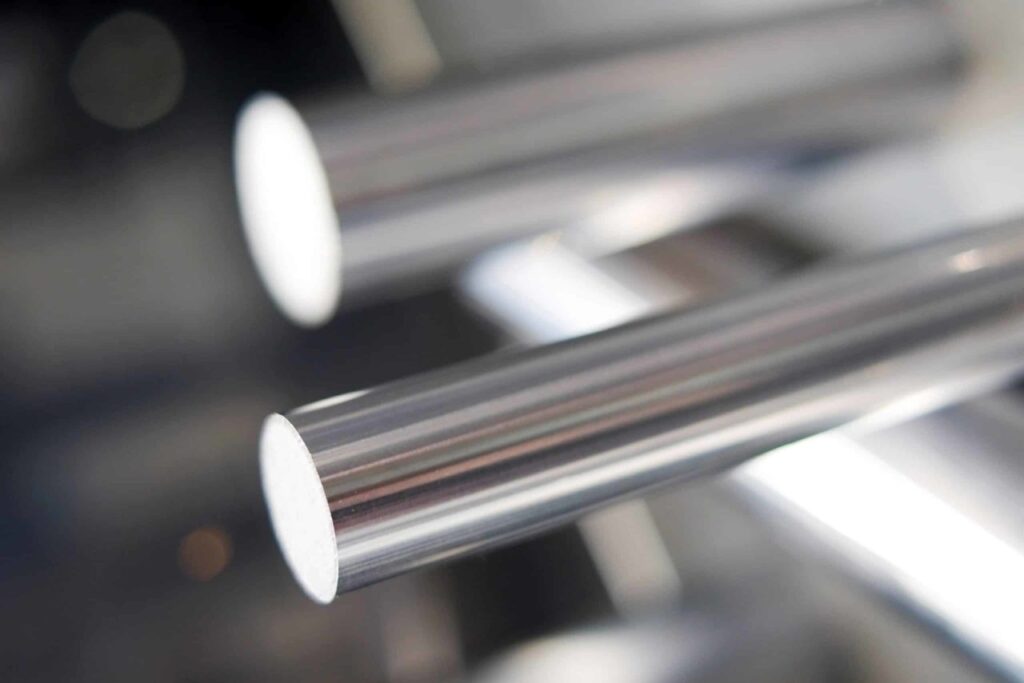

Renowned expertise in protecting and restoring the functionality of mechanical and hydraulic parts.

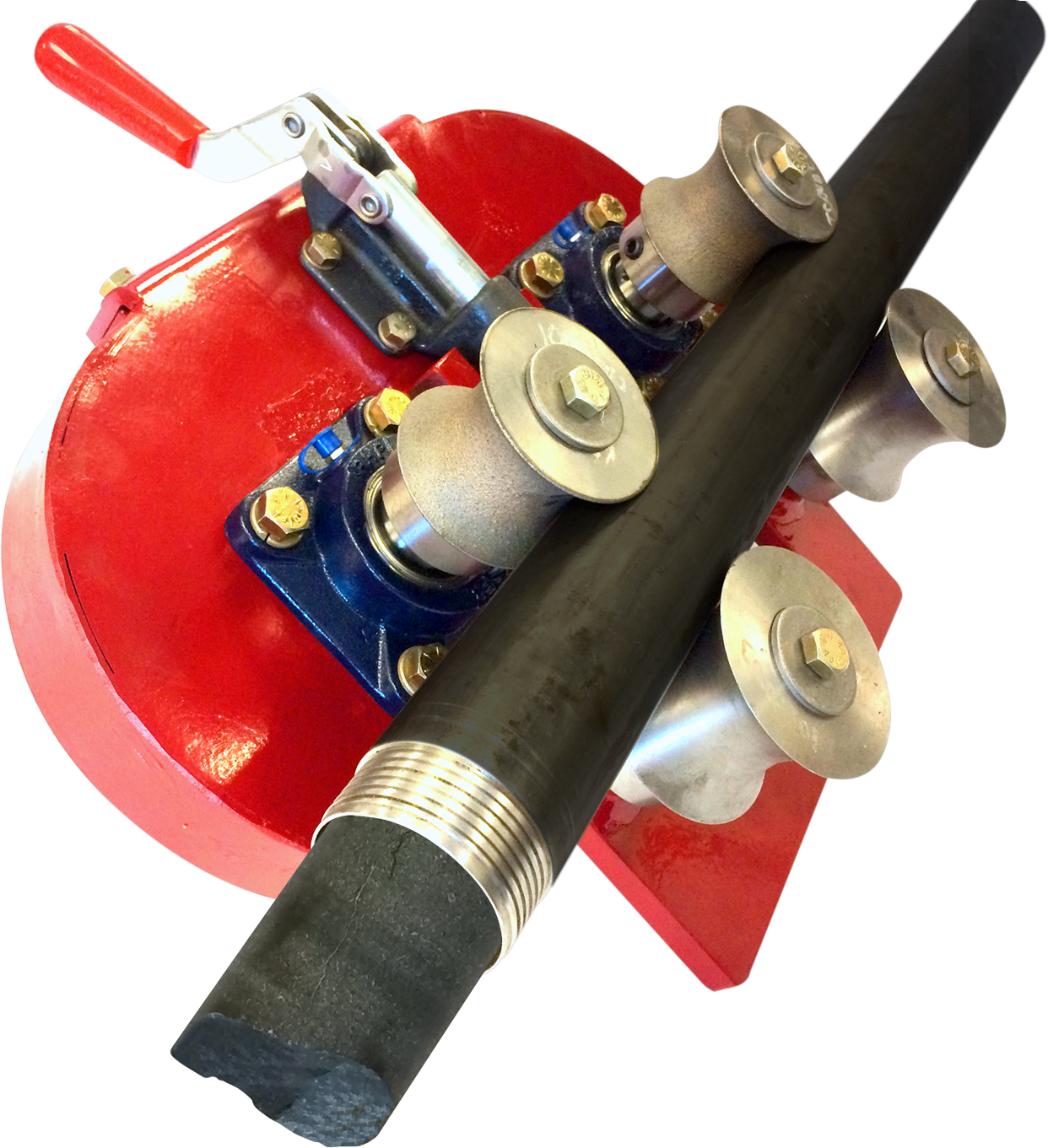

HARD CHROME PLATING

We are recognized experts in repairing and coating new parts for:

- Hydraulic cylinders and frames

- Bearing seats and driveshaft seals

- Rulers, planing tables, and flat and toothed rollers for woodworking

Capacity

- 5 high-capacity baths (12′ to 20′ long)

- 1 dechroming bath

- Plant operates 24/7

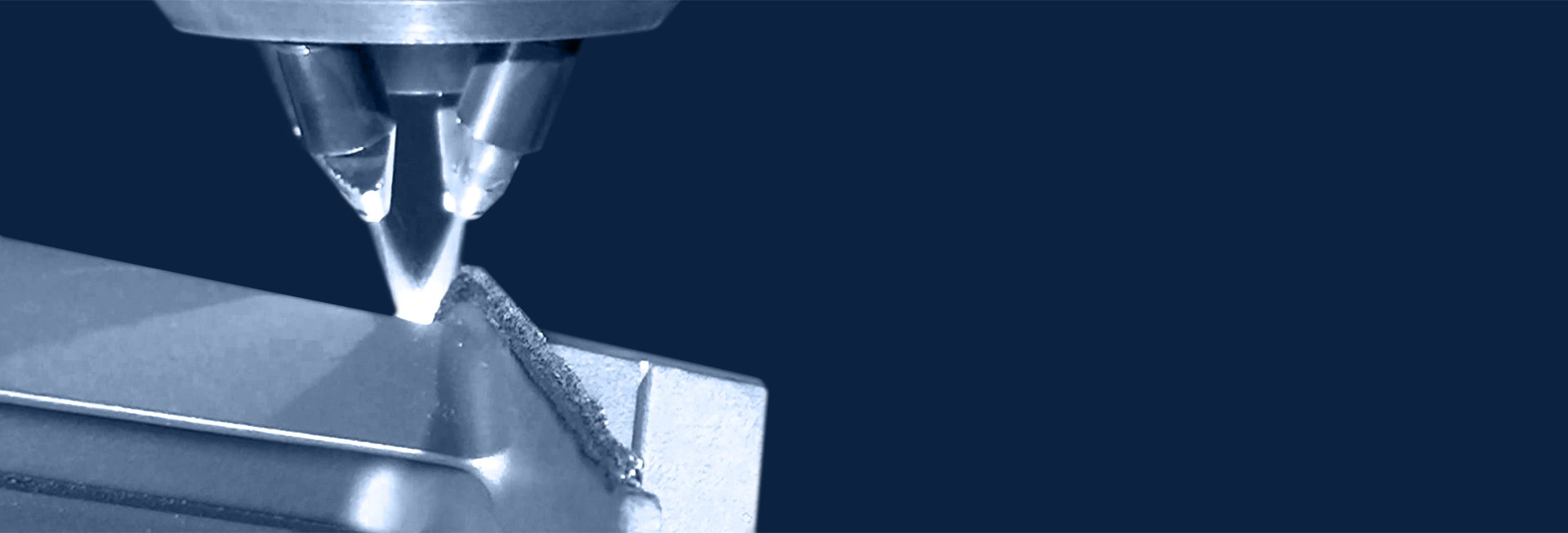

DIRECTED ENERGY DEPOSITION

Also known as laser cladding or DED, directed energy deposition uses a laser beam on the surface of the part to create a molten pool into which the laser-melted coating material is fed.

Capacity

- UL and conventional laser cladding

- Maximum part length: 4 m ≈ 157″

- Minimum inside diameter: 7 cm ≈ 2.7″

- Maximum outside diameter: 76 cm ≈ 30″

GRINDING AND POLISHING

We have been recognized for over 25 years for our expertise in grinding and polishing flat and cylindrical surfaces.

Capacity

- Cylindrical grinding or polishing: up to 40″ ⌀ x 170″

- Flat grinding: up to 12″ x 59″

- Grinding inside diameter: 2″–16″ ⌀ x 16″ depth

TECHNICAL SERVICES

Our engineering team analyzes and understands the metallurgy and characteristics of coatings. We also pride ourselves on our thorough quality assurance system.

Capacity

- Quality control: dimensional tolerance, surface finish, thickness, hardness, salt spray, and others

- Metallurgical analysis

- Application lab

OUR COATINGS

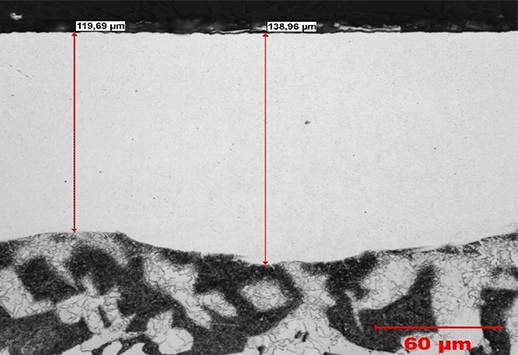

Developed in collaboration with the Center de metallurgie du Québec (CMQ), UL coatings use a DED coating process to prevent wear and corrosion in harsh environments.

Features and Benefits

- Our UL coatings are metallurgical alloys to replace hard chrome from a laser deposition hardfacing process. The metallurgical matrices can be adapted according to the characteristics sought and the context of application.

- They have unique properties due to the metallurgical bond to the substrate, which means it is significantly stronger than a chemical bond from a hard chrome plating process or thermal spray.

- The deposit has less than 1% dilution of the substrate, it is 100% dense with no porosity or cracks which makes it extremely effective against corrosion.

- Coatings can be deposited as a thin layer, allowing parts to be recharged very quickly with high energy efficiency.

OUR PRODUCTS

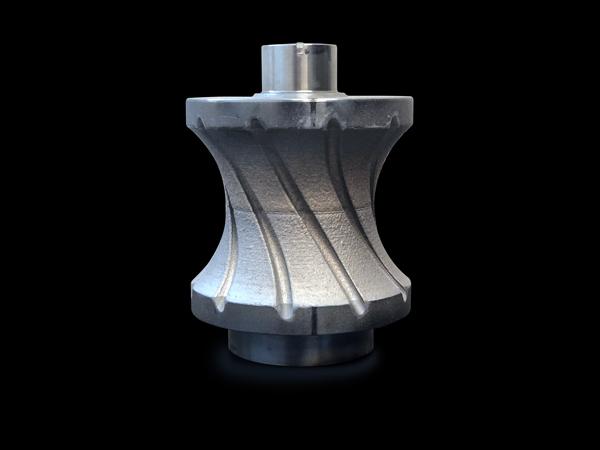

Tekad steel mill rolls

Heavy-duty steel

We manufacture and repair a full range of steel mill rolls. Our rolls are designed to replace existing OEM rolls.

Tekad diamond rolls

Diamond-clad steel

Coating composed of a metallic binder. It can contain diamond particles whose tips ensure better adherence to metal.

CONTACT US

WRITE TO US

CONTACT INFORMATION

2735 Rue Jules Vachon

Trois-Rivières (QC) G9A 5E1

T : 1-877-807-2739